RFGB Compact Horizontal and Vertical Fixture

RFGB Compact Horizontal and Vertical Fixture

This versatile and compact precision, servo rotary fixture is ideal for machining centres and can be used in both the horizontal and vertical orientation. The unit can be specified and built to suit the machine or application if space is tight with the internal arrangement changed to suit. The unit can have a pattern on one side or two. The RFGB-HV can be moved from horizontal to vertical orientation as required. The Standard low backlash design gives high accuracy at an affordable price.

The RFGB is available in a wide range of configurations some of the options include;

- Platen, Chuck or mounting boss

- Mount on one or both sides

- Central through hole

- Hydraulic Clamping, Electro-mechanical brake or gearing holding only

- Live machining, position and park or both

- Horizontal or Vertical

- Table mounting to suit the machine or machines it is to be used on

The Unit Shown here has the following;

- 250mm Platen Prepared for Customer Fixture

- Platen T-Slot

- 50mm Central Through Hole

- Hydraulic Clamping

The RFGB-HV, as with all the  Rotary units, can be either connected directly into and existing machine or connected to the

Rotary units, can be either connected directly into and existing machine or connected to the

Positioning and control system for fixtures and axes

Positioning and control system for fixtures and axes  See below.

See below.

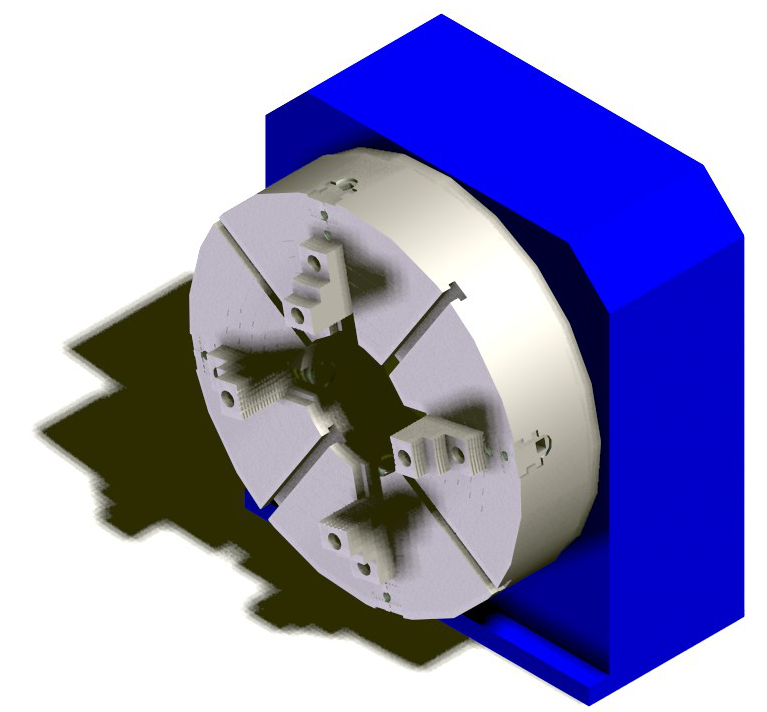

RVOC Oil Country, Large through hole Precision Servo Dividing Head

RVOC Oil Country, Large through hole Precision Servo Dividing Head

Oil Country Dividing Heads add the ability of extensive precision Shaft based work to a milling machine. This precision, servo rotary fixture affords the full versatility to carry out Oil and Shaft related work in an efficient and precise manner. The RVOC Range of units range from 300mm Diameter to 1500mm with Large through holes to suit. The combination of High accuracy measuring, precision drive, high force clamping and full A axis capabilities of the unit allow high quality, reliable and fast production of your components.

The Unit Shown here has the following;

- High accuracy precision worm

- Direct position feedback from a central shaft mounted 2.5arc seconds accuracy encoder

- A axis Live machining

- A axis Stationary machining

- Maximum permissibly load with suitable workpiece support (steadies etc) = 11,000 kg

- Hydraulic clamping

- 4 Jaw 800mm Chuck

- Top Jaws reversible full face or stepped

- Top Jaws positionable on master jaw for optimum clamping

- 317.5mm (12.5 Inch) hole Chuck

- Jaws capable of holding 100mm Diameter tube

The RVOC, as with all the  Rotary units, can be either connected directly into and existing machine or connected to the

Rotary units, can be either connected directly into and existing machine or connected to the

Positioning and control system for fixtures and axes

Positioning and control system for fixtures and axes  See below.

See below.

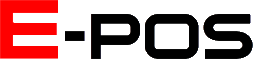

RTDS Large Precision Servo Rotary Table

RTDS Large Precision Servo Rotary Table

This large Table is ideal for multiple side machining of a component, allowing 5 side machining of the component from one set up. The large load carrying capacity and high precision bearings offer excellent accuracy capabilities and a very useful addition to you milling of boring machine. The table can be used with your existing machine or provided with a machine from the Seymour Range, the chose is yours. The ability of controlling the table using the Seymour E-POS system allows the precision extension of your existing machine without the need to retrofit the existing CNC Control. If available your machines external MCodes can be used to position the table from your existing machines CNC Program.

The RTDS is available in a wide range of configurations some of the options include;

- Table Loads: up to 60,000kg

- Table Shape: Round or Square

- Table Sizes : 1000m up to 2500mm

- T-Slots for fixture and work piece clamping

- Dedicated fixing points if required

- Central precision alignment bore if required

- Absolute or incremental Measuring systems

- Indexing accuracy +/- 5 Arc Seconds

- Low friction bearings

- Clamping system

- Automatic lubrication

- Keyed to assist with lining on the machine table or Floor plates

- permanent or removable Lifting points

- Integration into CNC, or Stand alone possibilities

- Full Machine and CNC integration available

- Ask about your requirements

The RTDS, as with all the  Rotary units, can be either connected directly into and existing machine or connected to the

Rotary units, can be either connected directly into and existing machine or connected to the

Positioning and control system for fixtures and axes

Positioning and control system for fixtures and axes  See below.

See below.

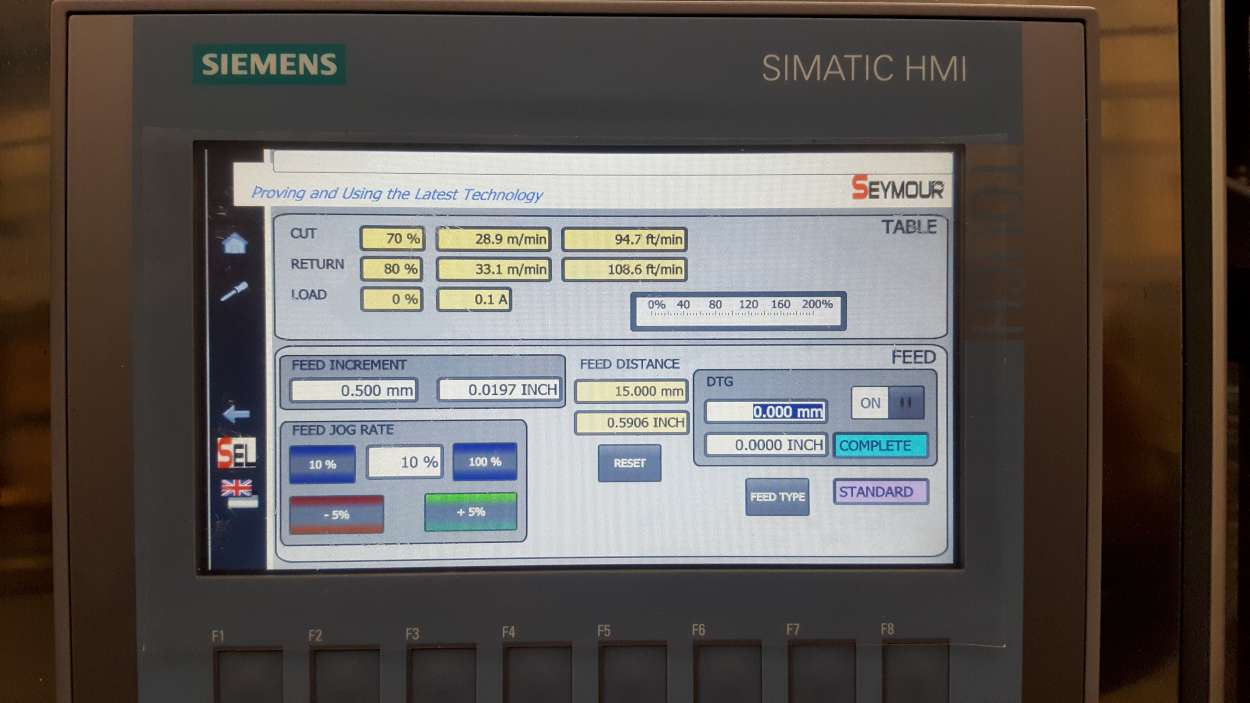

Servo Positioning control for Rotary Fixtures

Servo Positioning control for Rotary Fixtures

The E-POS Positional control system for Machine attachments has been developed from the

product line. The E-NC product has been in continual development for nearly 20 Years The origins of the product line are in the Rail industry with the Motion control, positional control and sequencing of Rail planers. The Versatile E-POS system con be configured to suit any application ranging from a simple single axis manual motion to multiple axis synchronous positioning. The system can be programmed with sequenced steps or just jogged. bespoke routines can be created or configurable programs. The system is very flexible.

product line. The E-NC product has been in continual development for nearly 20 Years The origins of the product line are in the Rail industry with the Motion control, positional control and sequencing of Rail planers. The Versatile E-POS system con be configured to suit any application ranging from a simple single axis manual motion to multiple axis synchronous positioning. The system can be programmed with sequenced steps or just jogged. bespoke routines can be created or configurable programs. The system is very flexible.

The E-POS system allows for a Rotary fixture to be used on many machines and can be used differently on each machine. as an Example in a machine shop there might be a three different machine, all of which could use the rotation fixture, a conventional manually operated milling machine, A simple milling machine with a 3 axis CNC and a Higher spec CNC milling machine with a CNC that has the ability to have an integrated 4th axis. A single Rotary fixture could be used and put on each of the 3 machines when needed;

- Conventional manual machine: The Rotary fixture is completely controlled by the Seymour E-POS and then the machining is carried out manually.

- Simple 3 Axis Milling machine: The Rotary fixture is jogged by the Seymour E-POS and a program sequence is entered into the E-POS, The CNC then uses its External MCodes to step through the E-POS sequence as needed and the CNC machines the component whilst being in control of the rotary motions as a dividing or indexing Head.

- High Spec CNC: The E-POS system is switched into External control mode and the Milling machines CNC controls the Rotary fixture as a full positioning and Live 4th axis.

The E-POS E-NC system can be configured and expanded in many ways to suit the requirements and some of the features include;

- Axis control from 1 to any number of axes

- Control of Hydraulics and Pneumatics with clamping and releasing sequencing

- Jogging

- Positioning

- synchronised motions

- Rotary and linear axes

- Travel limits

- Programmed operation

- Preset sequences

- Remote diagnostics / Machine monitoring

- Programming over the factory network

- External Control Mode - interface the axes direct with a existing machines CNC

- Hand Held pendant control or fixed operating station

- MCode control from another machine

- MCode feedback to another machine

- .... What ever you need

|

|

Email:- info@seymour-eng.com |

|

Siddal Hall Works, Phoebe Lane, Halifax, ENGLAND, HX3 9AS |  |

| TEL:- +44 (0) 1422 362 135 | FAX:- +44 (0) 1422 322 511 |